.

One of the most significant advantages of gasification is its potential to reduce greenhouse gas emissions. When biomass is used as feedstock, the carbon dioxide released during gasification is roughly equal to the amount absorbed by the plants during their growth, resulting in a closed carbon loop. This makes gasification a carbon-neutral process, provided it is managed sustainably.

In today’s fast-paced world, the need for enhanced productivity and effective time management has never been more critical. The rise of technology has paved the way for innovative solutions that can significantly streamline our daily tasks and responsibilities. One such innovation is the concept of the smart organizer. This multi-functional tool not only helps individuals manage their time but also integrates various aspects of life, ensuring a holistic approach to productivity.

The importance of natural gas filtration cannot be overstated. Impurities in natural gas can lead to a range of operational issues, including pipeline corrosion, reduced efficiency of combustion systems, and increased emissions of harmful pollutants. For instance, the presence of water can cause the formation of hydrates, which can block pipelines, while hydrogen sulfide is a toxic compound that poses severe health risks. Furthermore, contaminants can affect the performance of gas appliances and engines, leading to costly repairs and inefficiencies. Thus, effective filtration is essential not only for regulatory compliance but also for the longevity and reliability of gas infrastructure.

In summary, appliance regulators play a crucial role in the safe and efficient operation of home appliances. By managing variables such as pressure and temperature, these devices not only enhance safety but also improve energy efficiency and prolong appliance lifespan. Adherence to established standards ensures that these regulators function effectively, protecting consumers and promoting sustainable practices. As technology continues to evolve, the importance of appliance regulators will only grow, reinforcing their place as essential components in our daily lives.

- Industrial Processes Factories and manufacturing plants often require gas for power generation, heating, and various chemical processes, all of which rely on precise pressure regulation.

In conclusion, organizations dedicated to pressure reduction play a vital role in promoting mental well-being across various demographics. Through education, support, policy advocacy, and innovative solutions, they help individuals navigate the complexities of modern life. As awareness of mental health continues to grow, these organizations are paving the way for healthier communities, where individuals can thrive despite the pressures they face. By fostering resilience and providing essential resources, they contribute significantly to the overall quality of life, making the world a more supportive place for everyone.

One of the most significant advantages of using shut-off valves is the ability to isolate sections of a pipeline. This feature is particularly important during maintenance work, as it allows technicians to service a portion of the system without disrupting the entire operation. For instance, in a large manufacturing facility, if a section of the water supply needs repairs, operators can simply close the shut-off valves on the upstream and downstream ends of the section being serviced. This isolation minimizes downtime and prevents disruption to production.

City Gate Station A Nexus of Urban Connectivity

Moreover, electric water heaters typically require less maintenance than gas models. They do not need venting, which can complicate installation, and there are fewer components that can fail over time. This not only makes them easier to install but also results in lower long-term maintenance costs.

Understanding Pressure Vessels Significance, Design, and Safety

There are several types of electric valves tailored to different applications

Environmental Considerations

Transportation is a vital link in the organization of natural gas, as it is typically found far from where it is consumed. Two primary methods are used for transporting natural gas pipelines and liquefied natural gas (LNG) carriers. Pipeline transportation is the most common method, facilitating the efficient transfer of gas across the globe. However, when gas needs to be shipped over long distances or across oceans, compressing it into a liquid state reduces its volume and makes it feasible for maritime transport. The LNG market has seen substantial growth, supported by investments in specialized terminals and fleets.

In an era of increasing energy demand and environmental concerns, the quest for sustainable energy solutions has never been more vital. Among the array of technologies emerging to address these needs, gasification stands out as a promising method for converting various feedstocks into valuable energy. Central to this process is the gasifier, a device that plays a pivotal role in transforming organic or fossil-based materials into synthetic gas, or syngas, which can be used for electricity generation, heating, and even as a precursor for fuels.

However, it is essential to recognize that “al-fasle” is not only about separation; it also underscores the opportunity for dialogue and connection. Within every divide lies the potential for understanding and collaboration. Engaging with the “other” involves overcoming the fear that often accompanies differences. By stepping beyond our comfort zones and embracing curiosity, individuals can explore unfamiliar perspectives, leading to richer interactions and a greater appreciation for diversity.

Operational safety should never be compromised; thus, regular training for personnel involved in the operation and maintenance of pressure vessels is essential. Understanding the principles of pressure vessel operation, potential hazards, and emergency procedures can significantly mitigate risks.

The Importance of Pressure Vessels

- Energy Sector In the oil and gas industry, accurate measurement of gases is critical for exploration, extraction, and distribution. It helps in estimating reserves and detecting leaks in pipelines.

The Role of Smart Regulators in Modern Governance

4. Compliance with Regulations Energy companies are subject to stringent regulations regarding the safe handling of natural gas. The use of appropriate safety valves is often a regulatory requirement, ensuring that companies operate within legal standards to protect workers, the public, and the environment.

Consequences of Neglecting Safety Valves

Despite its advantages, the transition to CNG is not without challenges. The initial investment in CNG vehicles and infrastructure can be significant, and there are concerns regarding the storage and distribution of natural gas. Safety measures are paramount, as natural gas is flammable, necessitating rigorous standards and practices.

- Direct-Acting Pressure Reducing Valves These are the most common types and work by using a spring mechanism that responds directly to changes in pressure. They provide quick reactions to pressure fluctuations.

Innovation in shut-off valve technology has also led to the development of automated systems that enhance control and monitoring. Automated shut-off valves can be integrated with sensors and control systems to provide real-time data on flow conditions, pressure levels, and valve status. This technology enables operators to make informed decisions quickly, improving overall system responsiveness and reducing the risk of human error. Additionally, advancements such as smart valves can communicate with central monitoring systems, allowing for predictive maintenance and less downtime.

Ultimately, the journey towards bridging divides requires a conscious effort to engage with the concept of “al-fasle.” It is an invitation to challenge our assumptions, confront our biases, and actively seek to understand rather than judge. By recognizing the divides in our lives and communities, we can work towards breaking them down. Every small step—whether through education, dialogue, or community engagement—contributes to a broader landscape of connection.

What is a Gas Coalescer Filter?

In conclusion, gas pressure regulators are indispensable devices that maintain safe and efficient operations in various applications. By controlling the pressure of gases in distribution systems, they help prevent accidents and equipment failures. As industries continue to grow and evolve, the technological advancements in gas pressure regulation will undoubtedly play a vital role in enhancing the safety and reliability of gas systems. Understanding the nuances of these regulators is essential for professionals working in gas-related fields, ensuring they can effectively manage the complexities of gas pressure control.

Natural gas filters are designed to remove impurities and contaminants from the gas stream. These impurities can include water, dust, sand, and other particulate matter that can accumulate during natural gas extraction, processing, and transportation. The presence of these contaminants can lead to several issues, including corrosion of pipelines, reduced efficiency of gas-burning appliances, and potential safety hazards such as explosions or leaks.

At its core, a gas pressure regulator is a mechanical device that reduces the pressure of the incoming gas to a predetermined output pressure. This is particularly important because gases are often supplied at relatively high pressures, which can be dangerous if not managed properly. By regulating the pressure, the device helps prevent potential accidents, such as leaks or explosions, that can occur if the pressure is too high.

Support groups are another essential component of organizations focused on pressure reduction. Groups like the Anxiety and Depression Association of America (ADAA) create safe spaces for individuals to share their experiences and connect with others facing similar challenges. This sense of community can alleviate feelings of isolation and foster a supportive network where individuals can receive encouragement and understanding. Hearing from others who have successfully navigated their stressors can provide hope and motivation to seek improvements in one’s own life.

Understanding Gas Pressure Reducers Key Components in Gas Management Systems

Safety Regulations and Standards

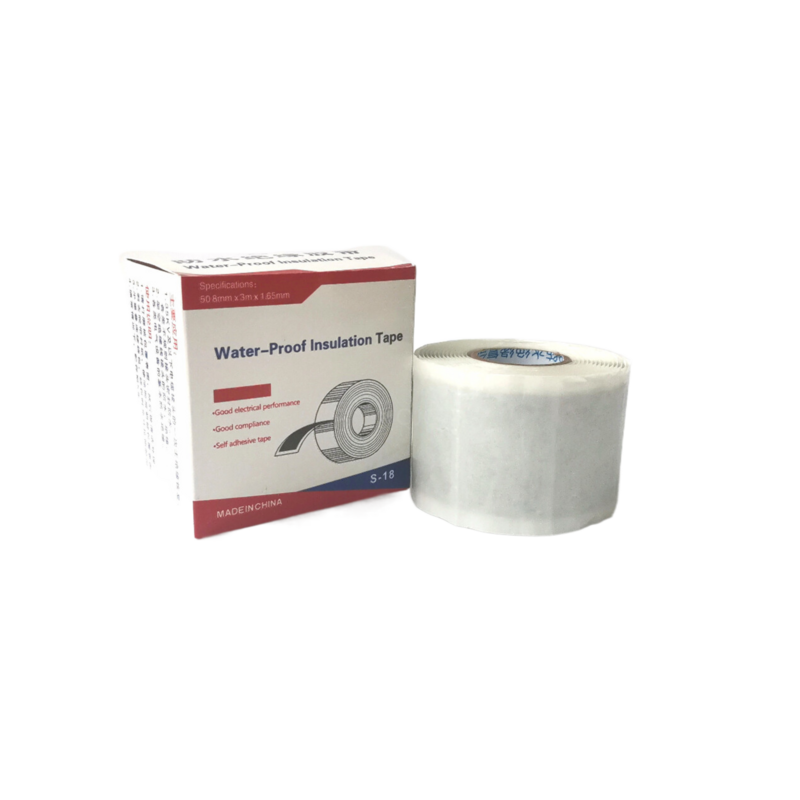

Simply clean the surface you want to seal, cut the tape to the desired length, peel off the backing, and press the tape firmly into place Simply clean the surface you want to seal, cut the tape to the desired length, peel off the backing, and press the tape firmly into place

Simply clean the surface you want to seal, cut the tape to the desired length, peel off the backing, and press the tape firmly into place Simply clean the surface you want to seal, cut the tape to the desired length, peel off the backing, and press the tape firmly into place leak stopper rubber flexx waterproof tape 4. That’s it – no special tools or equipment required. And because Leak Stopper Rubber Flexx Waterproof Tape is self-adhesive, there’s no need to worry about messy glues or sealants.

leak stopper rubber flexx waterproof tape 4. That’s it – no special tools or equipment required. And because Leak Stopper Rubber Flexx Waterproof Tape is self-adhesive, there’s no need to worry about messy glues or sealants.Measure and Cut: Cut the desired length of silicone tape. Make sure it's slightly longer than the area you need to cover.

Moreover, Flex Tape is resistant to extreme temperatures, which plays a vital role in its effectiveness. Whether it is the frigid cold of winter or the sweltering heat of summer, the tape maintains its adhesive properties, ensuring that repairs remain intact throughout the year. This reliability brings peace of mind to users who rely on it for critical fixes.

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

industrial floor marking tape. It requires minimal downtime, making it ideal for busy facilities. The tape can be easily removed without leaving residue, allowing for quick changes or updates when needed.

industrial floor marking tape. It requires minimal downtime, making it ideal for busy facilities. The tape can be easily removed without leaving residue, allowing for quick changes or updates when needed. However, it might be more cost-effective in the long run as it reduces the need for frequent replacements However, it might be more cost-effective in the long run as it reduces the need for frequent replacements

However, it might be more cost-effective in the long run as it reduces the need for frequent replacements However, it might be more cost-effective in the long run as it reduces the need for frequent replacements black electrical tape price.

black electrical tape price.Insulation tape is a type of electrical tape used primarily to insulate electrical wires and prevent short circuits. It is typically made from a flexible plastic material, often PVC, that is resistant to electrical currents, moisture, and abrasion. The red insulation tape, in particular, provides a distinctive color coding that makes it easily identifiable in various settings.

No protective equipment or specialist tools are required to use self-amalgamating tape, and a pair of scissors to cut the tape is all that is needed. The tape features a peel-away backing paper (to stop it from sticking to itself before needed) that has to be removed prior to use. Once the correct length has been cut, and the backing removed, the tape can be stretched and applied; when the tape is being wrapped around a cable, for example, ensure that each layer overlaps the previous. Overlapping in this way enables a stronger bond between layers and a 50% overlap is usually recommended, with 3-4 layers of tape being advised. Stretching the tape as you go will ensure a tighter wrap is created and will help the tape to stick to itself more effectively. The bond between the layers of tape will usually take only a few minutes to form but is capable of enduring for years.

have established themselves as reliable suppliers, offering customized solutions at competitive prices have established themselves as reliable suppliers, offering customized solutions at competitive prices

have established themselves as reliable suppliers, offering customized solutions at competitive prices have established themselves as reliable suppliers, offering customized solutions at competitive prices pvc electrical tape manufacturers.

pvc electrical tape manufacturers. fire resistant adhesive tape. Its ability to resist flames and heat helps to protect sensitive components and prevent fires, enhancing vehicle safety.

fire resistant adhesive tape. Its ability to resist flames and heat helps to protect sensitive components and prevent fires, enhancing vehicle safety.